HTE Series Multi Stage Cylinder Bolt Tensioner

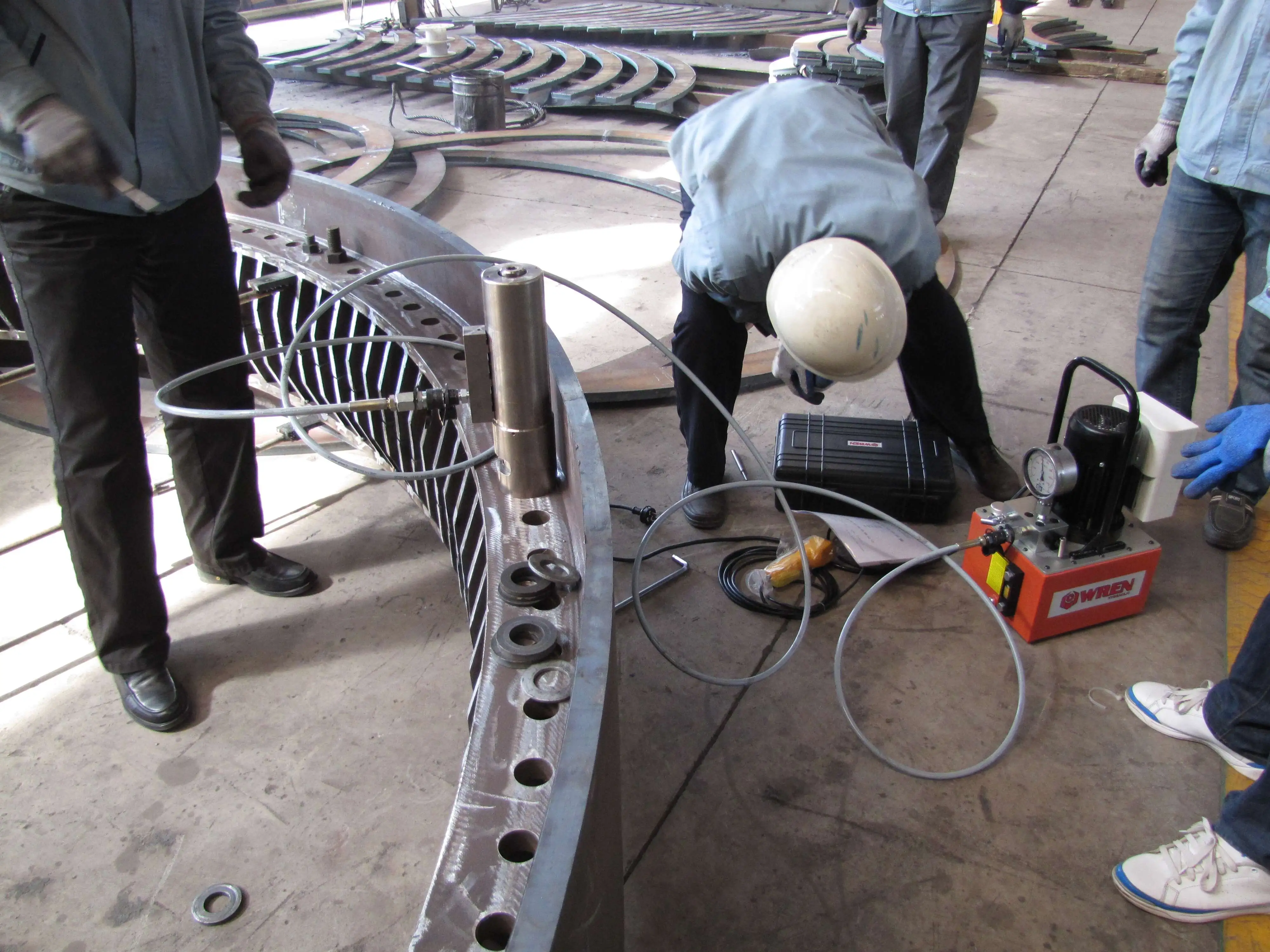

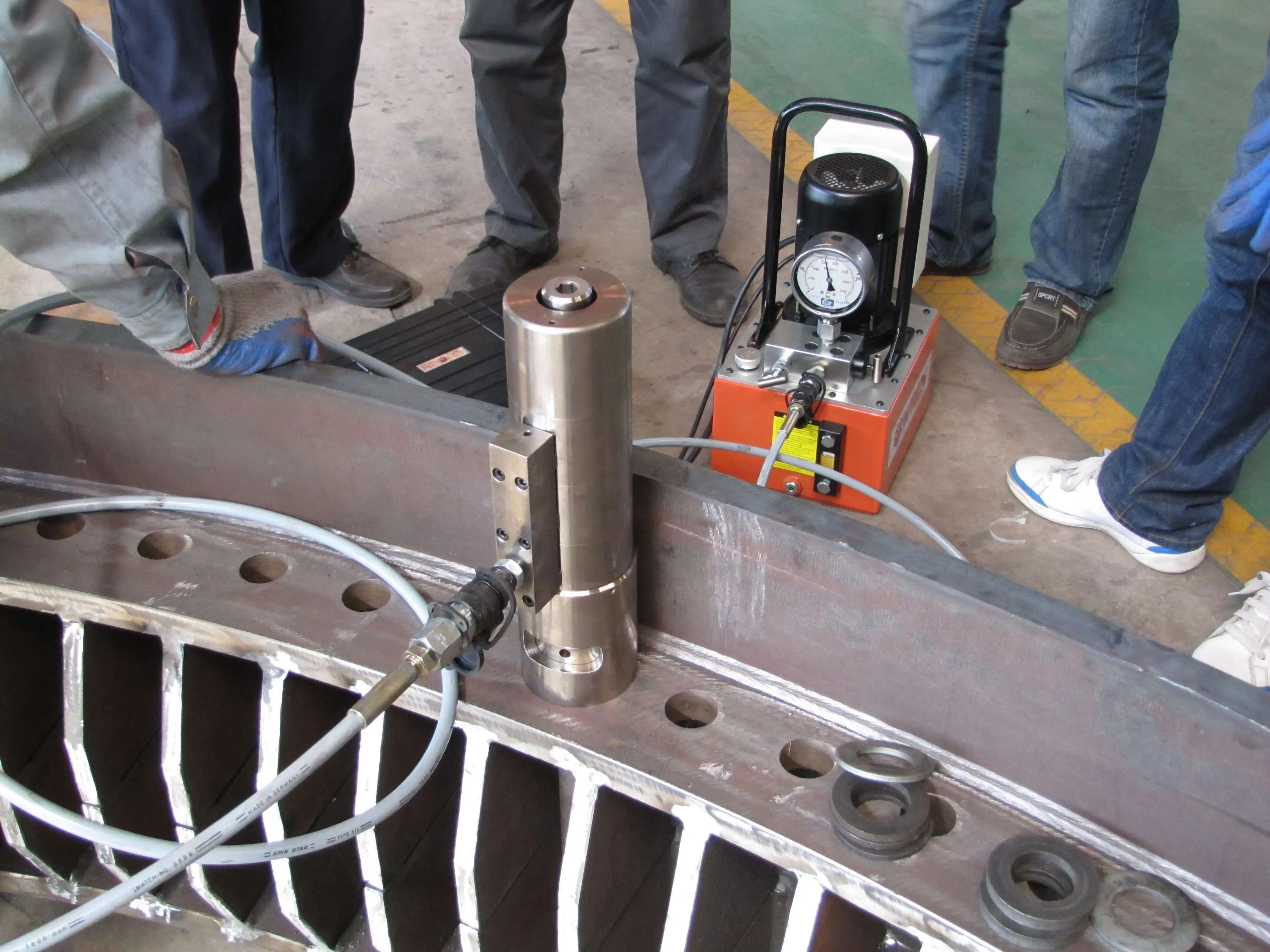

The WREN multi-stage bolt tensioner adopts a miniaturized design, greatly enhancing operability in narrow working spaces. The integrated spring-loaded mechanism allows for automatic socket-to-nut alignment, effectively reducing operational complexity. WREN can customize various types of hydraulic bolt tensioners according to the different application requirements of extra-large equipment in industries such as chemical engineering, wind power, nuclear power, aerospace, and heavy machinery. WREN offers personalized customization based on performance indicators including tensile force, adjustment accuracy, and data recording.

The WREN multi-stage bolt tensioner adopts a miniaturized design, greatly enhancing operability in narrow working spaces. The integrated spring-loaded mechanism allows for automatic socket-to-nut alignment, effectively reducing operational complexity. WREN can customize various types of hydraulic bolt tensioners according to the different application requirements of extra-large equipment in industries such as chemical engineering, wind power, nuclear power, aerospace, and heavy machinery. WREN offers personalized customization based on performance indicators including tensile force, adjustment accuracy, and data recording.

Product Details

-Multi-stage cylinder, minimizes equipment size, suitable for operations in narrow spaces

-Automatic recovery and stroke protection function, suitable for frequent operation

-Built-in explosion-proof device, provides safety protection

-700-1500bar working pressure

-Multi-stage cylinder, minimizes equipment size, suitable for operations in narrow spaces

-Automatic recovery and stroke protection function, suitable for frequent operation

-Built-in explosion-proof device, provides safety protection

-700-1500bar working pressure

| Model | Maximum working pressure | Maximum output pressure | Maximum Stroke | Effect area | Outside diameter |

Bolt | Nut size | Weight |

| bar | kN | mm | mm² | mm | mm | kg | ||

| HTE24 | 1350 | 307 | 7 | 2274 | 59 | M24 | 36 | ≈5 |

| *HTE30 | 1350 | 461 | 7 | 3417 | 72 | M30 | 46 | ≈6.6 |

| *HTE33 | 1350 | 595 | 7 | 4407 | 79 | M33 | 50 | ≈8 |

| *HTE36 | 1350 | 680 | 10 | 5037 | 84.5 | M36 | 55 | ≈10.7 |

| *HTE39 | 1350 | 800 | 10 | 5926 | 91.5 | M39 | 60 | ≈12.8 |

| *HTE42 | 1350 | 922 | 10 | 6830 | 98.5 | M42 | 65 | ≈16.1 |

| HTE45 | 1350 | 1086 | 10 | 8047 | 107 | M45 | 70 | ≈20.8 |

| *HTE48 | 1350 | 1290 | 10 | 9604 | 116 | M48 | 75 | ≈22 |

| HTE52 | 1350 | 1535 | 10 | 11370 | 126.8 | M52 | 80 | ≈24 |

| HTE56 | 1350 | 1660 | 10 | 12296 | 131 | M56 | 85 | ≈24 |

| HTE64 | 1250 | 2350 | 10 | 18800 | 147.8 | M64 | 95 | ≈47.2 |

| *Common Specifications for Wind Power | ||||||||

| Model | Maximum working pressure | Maximum output pressure | Maximum Stroke | Effect area | Outside diameter |

Bolt | Nut size | Weight |

| bar | kN | mm | mm² | mm | mm | kg | ||

| HTE24 | 1350 | 307 | 7 | 2274 | 59 | M24 | 36 | ≈5 |

| *HTE30 | 1350 | 461 | 7 | 3417 | 72 | M30 | 46 | ≈6.6 |

| *HTE33 | 1350 | 595 | 7 | 4407 | 79 | M33 | 50 | ≈8 |

| *HTE36 | 1350 | 680 | 10 | 5037 | 84.5 | M36 | 55 | ≈10.7 |

| *HTE39 | 1350 | 800 | 10 | 5926 | 91.5 | M39 | 60 | ≈12.8 |

| *HTE42 | 1350 | 922 | 10 | 6830 | 98.5 | M42 | 65 | ≈16.1 |

| HTE45 | 1350 | 1086 | 10 | 8047 | 107 | M45 | 70 | ≈20.8 |

| *HTE48 | 1350 | 1290 | 10 | 9604 | 116 | M48 | 75 | ≈22 |

| HTE52 | 1350 | 1535 | 10 | 11370 | 126.8 | M52 | 80 | ≈24 |

| HTE56 | 1350 | 1660 | 10 | 12296 | 131 | M56 | 85 | ≈24 |

| HTE64 | 1250 | 2350 | 10 | 18800 | 147.8 | M64 | 95 | ≈47.2 |

| *Common Specifications for Wind Power | ||||||||

Previous: NO MORE

Next: NO MORE